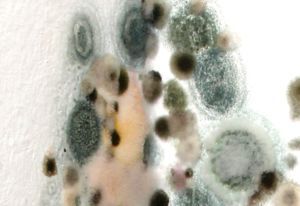

The Evolution of Mold Remediation

As the industry and processes of professional mold remediation have evolved, mold removal specialists have continually looked for ways to reduce the exhaustive labor and costs involved in eradicating the fungus.

In most cases, historically, eradicating mold has meant some form of aggressive or abrasive cleaning such as sanding, scraping, wire brushing, dry ice or soda blasting, followed by intensive sterilization with strong cleaners and fungicides.

All this work must be done following proper procedures that include building containment, the use of negative air pressure and personal protective equipment. And in many cases, large quantities of porous building materials must be gutted from the structure and completely replaced. This process is extremely labor-intensive and expensive.

But There’s Another Way

However, mold remediation professionals in the Carolinas hit upon a simpler, less costly process that has proven to meet the highest mold remediation clearance testing standards, the Carolina Protocol.

Abbotts employs the Carolina Protocol to completely eradicate mold infestation while saving time, labor and money.

The Carolina Protocol process involves the use of regular hydrogen peroxide (at high concentration) as the cleaning agent. The protocol is detailed below and should be used by trained technicians wearing proper personal protective equipment.

1. A complete and detailed inspection of the contaminated site is performed.

2. An indoor environmental assessment is performed.

3. The mold remediation specialist crafts the remediation plan.

4. The site is secured, containment for the work site is completed and negative air pressure is established.

5. Based on the protocol, demolition and removal of what material can and should be removed is performed.

6. All surfaces are HEPA vacuumed.

7. The remaining structure (framing lumber, plywood, oriented strand board, etc.) is to be cleaned using hydrogen peroxide.

a. Most materials are dried to below 16 percent moisture content.

b. All affected surfaces are sprayed with hydrogen peroxide until they are visibly wet.

c. The hydrogen peroxide is allowed contact time to burn the mold.

d. All the surfaces are again HEPA vacuumed.

8. An EPA-registered biocide should be applied, following label directions, to ensure remaining microbes are destroyed.

9. An inspection is performed by the remediation specialist. This may include the use of a particle counter or other sampling tools or techniques.

10. The site is cleared.

The use of six to eight percent strength hydrogen peroxide — not the three or four percent sold in retail stores or pharmacies — as a cleaning agent is the key to the Carolina Protocol.

How Does Hydrogen Peroxide Remove Mold

Hydrogen Peroxide removes mold by oxidizing it, which is just chemically burning it.

Most of us have experienced a small cut and used hydrogen peroxide on the open cut. We have seen the bubbling action in the cut. This bubbling is the chemical release of oxygen, which is oxidation, the chemical burning of the contamination.

In the example of the cut, the bacteria are destroyed by oxidation. In the case of mold growing on framing lumber, the mold and its hyphae structure, the mold is destroyed by the same oxidation. Think of it like a very small fire burning the “forest” of mold. And the really unique part of this is the hydrogen peroxide also follows the roots of the mold down into the material on which it was growing, thus removing all traces of the mold.

Can Something This Simple Really Work

Mold remediation specialists have used the Carolina Protocol to successfully pass clearance testing on hundreds of jobs. The science is sound, and the results are indisputable. The Carolina Protocol works.